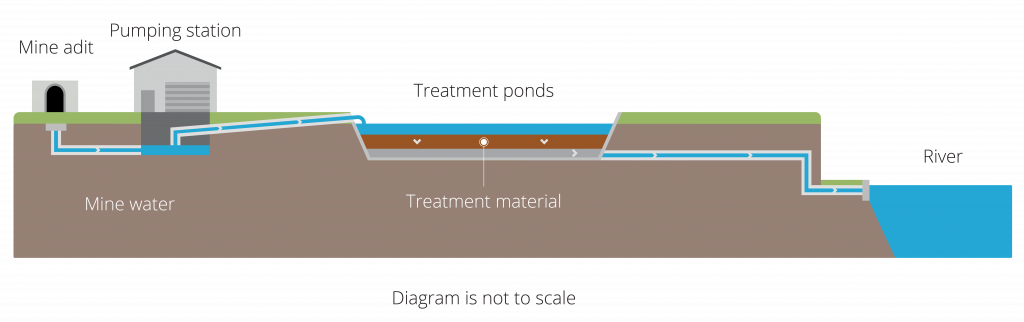

Where possible, the WAMM Programme prefers to use “passive” technologies which do not require continual supervision by people and have minimal input of chemicals or energy since these systems tend to have the lowest whole lifecycle costs. The design of treatment schemes is determined by the concentrations of metals and how much mine water needs to be treated. We commissioned international mine water treatment experts to identify the best available potential technologies to remove the metals from the mine water before it enters the river.

The proposed treatment scheme uses a series of ponds in which the metals are removed by encouraging naturally occurring geochemical, microbiological and ecological processes to occur within natural materials placed in the base of lined treatment ponds. Some of the sulphate present in the mine water is converted into dissolved sulphide which binds to the metals to form solids that are retained in the treatment layer. We expect that more than 90% of the metals will be removed by the treatment scheme.

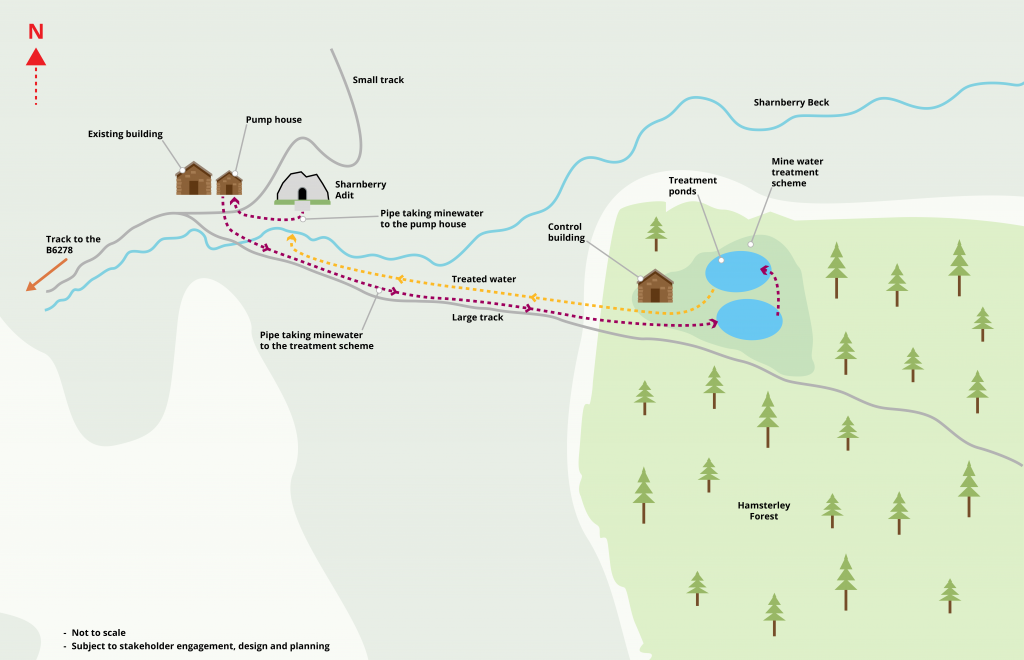

The Sharnberry treatment scheme is being designed to treat about 14 litres per second of mine water as this will deliver the most environmental benefits in terms of cleaning up the river. This means that not all the mine water can be treated all of the time. The mine water will be captured at the Sharnberry mine adit, taken in a buried pipe to the treatment ponds where approximately 90% of the metals will be removed, then returned to Sharnberry Beck near the adit.